From the daring dreams of Icarus to today’s supersonic aircraft, man has never stopped pushing back the limits of the sky.

At the heart of this aerial conquest lies a revolutionary invention: the jet engine. Powerful, complex and fascinating, this masterpiece of engineering transforms simple combustion into a phenomenal force capable of propelling hundreds of tons through the clouds.

But how does it really work? What physical principles and historical innovations made it possible?

Dive into the bowels of these mechanical giants, where science meets pure power, and discover the incredible story of the engines that changed the world.

The history of jet engines: a scientific and technical epic

Since ancient times, man has dreamed of conquering the skies. The myth of Icarus, who flies with wings made of bird feathers, illustrates this age-old quest. But it would take centuries for science and technology to turn this dream into reality.

Theoretical beginnings (16ᵉ-18ᵉ centuries)

In the 16ᵉ century, Leonardo da Vinci sketched the first flying machines inspired by birds. However, at the time, the only motive power available was still muscle power. The scientific foundations of flight would not emerge until the 17ᵉ and 18ᵉ centuries, thanks to the work of :

- Isaac Newton (laws of dynamics),

- Daniel Bernoulli (principle of aerodynamic lift).

Early achievements (19ᵉ century)

The industrial revolution paved the way for concrete experiments:

- In 1890, Frenchman Clément Ader managed to get his Éole, a steam-powered airplane inspired by the flight of bats, off the ground. Although not very maneuverable, it marked a crucial step forward.

- On December 17, 1903, brothers Orville and Wilbur Wright made the first powered, controlled flight with their Flyer, powered by an internal combustion engine.

The advent of the jet engine (20ᵉ century)

While early aircraft used propellers, the limitations of this technology prompted engineers to look for an alternative. Work on jet propulsion began as early as the 1930s, with pioneers such as:

- Frank Whittle (UK),

- Hans von Ohain (Germany).

The first operational jet aircraft, the Messerschmitt Me 262, entered service in 1944, revolutionizing modern aviation.

Today, jet engines power the majority of civil and military aircraft, offering speed, power and efficiency. This story of daring and innovation shows how mankind has pushed back the limits of what is possible.

How a jet engine works

Origin and evolution

The first jet engine, or turbojet, was designed by the Germans in 1939. It was, however, the fruit of centuries of research.

This video explains how today’s engines work:

The basic principle

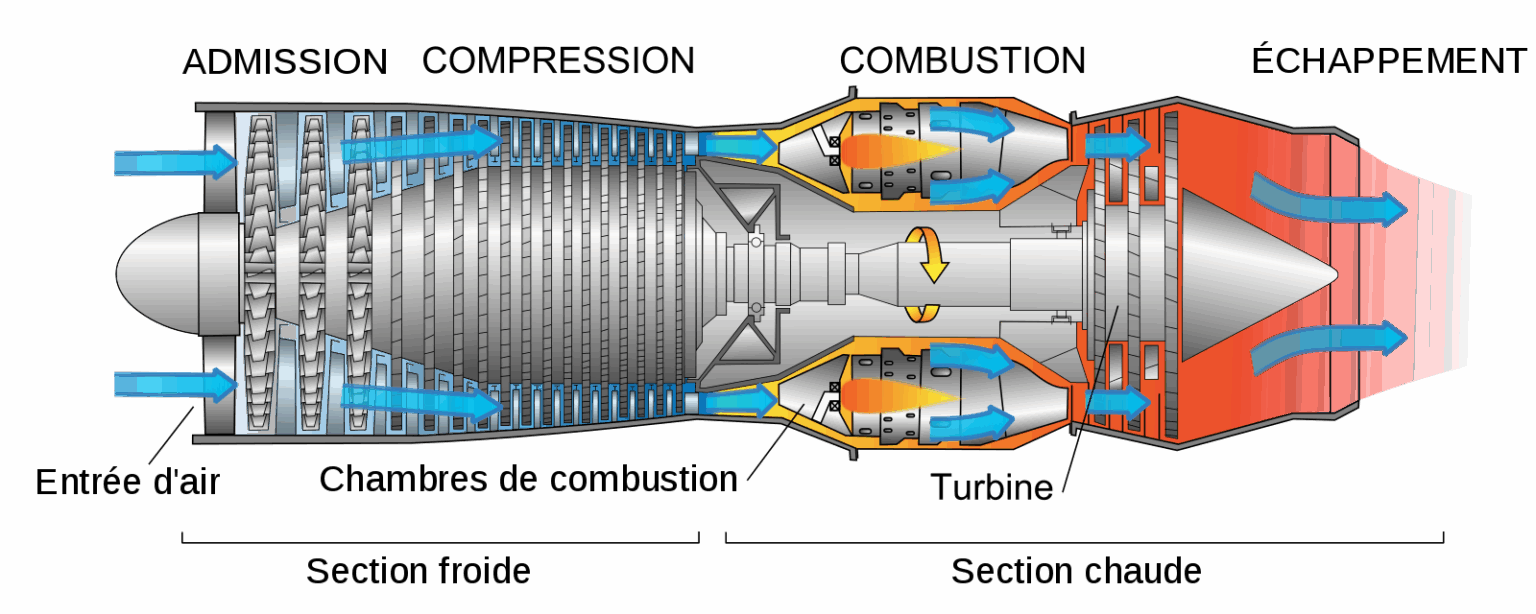

the operation of a jet engine is based on a precise sequence:

- Suction and compression

Air is drawn in by a blower, then continuously compressed.

- Combustion

The compressed air enters the combustion chamber, where it is mixed with kerosene and ignited. The resulting reaction expands gases at high temperature and pressure.

- Expansion and propulsion

The expanded gases are expelled backwards at very high speed through a convergent nozzle (which narrows), creating a forward thrust (according to Newton’s action-reaction principle).

- Continuous feed

As the gases leave the compressor, they drive a turbine located on the same axis as the compressor. The movement of the turbine causes that of the compressor, enabling the cycle to continue as long as the engine is powered.

Aerodynamic support

Propulsion alone is not enough: it’s the airflow over the wings that generates the lift needed to keep the plane flying.

Current challenges

Airlines and aircraft manufacturers are constantly working to:

- Reduce emissions (CO₂, particulates) by optimizing combustion chambers.

- Improve fuel efficiency, for example with high bypass ratio engines (such as turbofan engines).

- Reduce fuel consumption, a major economic and ecological challenge.

For a simplified visualization, this video explains the process.

Newton’s laws of motion

In the 17ᵉ century, Isaac Newton enunciated three fundamental laws governing classical mechanics:

- The principle of inertia: A body remains at rest or in uniform rectilinear motion unless a force acts on it.

- The principle of dynamics: The force exerted on an object is equal to its mass multiplied by its acceleration (F = m × a).

- The principle of reciprocal action (or action-reaction): Every action has a corresponding reaction, equal in intensity but opposite in direction.

Application to jet propulsion

Newton’s third law is at the heart of jet engine operation. When an aircraft ejects gases backwards at high speed, they exert a reaction force (thrust) that propels the aircraft forward. The faster and more massive the gas jet, the greater the thrust.

Aircraft flight and lift

This same law also explains how an aircraft stays aloft:

- The shape and inclination of the wings exert a downward force on the air (action).

- In response, the air exerts an opposite upward force, called lift, which compensates for the aircraft’s weight.

Thus, the compensation of forces (thrust, drag, lift and weight) enables stable, controlled flight.

(Note: these principles are also essential in astronautics, where rocket propulsion relies entirely on the ejection of gases in accordance with Newton’s third law)

The first jet engine: an aeronautical revolution

The beginnings: John Barber and the gas turbine (1731)

As early as 1731, the Englishman John Barber came up with a precursor concept for the turbojet engine, registering patents for an internal-combustion gas turbine.

His engine already featured the key elements: a compressor, a combustion chamber and a turbine, powered by fuel.

Unfortunately, the technologies of the time did not produce enough power to make it work properly.

The development of gas turbines was then eclipsed by the success of steam turbines, which were more efficient at the time. It wasn’t until the XXᵉ century that the idea resurfaced.

The modern era: Whittle, Von Ohain and jet propulsion

In the 1930s, the work of Romanian Henri Coandă and Frenchman Maxime Guillaume revived interest in jet propulsion. But it was British engineer Sir Frank Whittle who truly revolutionized the field.

In 1937, Whittle designed an innovative turbojet engine: instead of using a piston engine to compress the air, he installed a turbine downstream, harnessing the energy of the exhaust gases to drive the compressor. This architecture makes the engine more powerful and more economical than piston models.

Almost simultaneously, the German Hans von Ohain developed a similar engine for the Heinkel company. In 1939, the Heinkel He-178 became the world’s first jet aircraft. Its maiden flight was cut short, however, when a bird was sucked into the engine.

The arms race and the rise of modern aviation

The Second World War accelerated technological progress. Germany and the UK competed in a race for performance, while the USA and the USSR rapidly caught up after 1945. France, delayed by the Occupation, joined the competition later.

By the 1950s, turbojet engines were equipping the first civil aircraft, marking the start of a new era in air transport.

This innovation, born of a succession of failures and breakthroughs, definitively transformed aviation, offering faster, more efficient and more reliable aircraft.

Heinkel He-178 – Photo credit: Wikimedia Commons

What are the different types of jet engine?

There are several categories of jet engine, each adapted to specific needs:

1. Turbojet engines

Generally speaking, turbojet engines convert the chemical energy contained in a fuel into kinetic energy.

From the outset, the development of turbojet engines has been a major challenge for both the military and civilian sectors.

They are divided into two sub-types:

- Centrifugal compressor turbojet engines: Centrifugal compressor turbojet engines are simple and robust to manufacture. However, they require a large-diameter motor, which reduces the aircraft’s final speed.

- Axial-compressor turbojet engines: These are more powerful, thanks to a series of propellers that compress the air. However, they require more advanced materials.

In both cases, the engine must be able to withstand temperatures of up to 2000°C.

2. Turbofan engines

In a turbofan engine, a blower is placed in front of the compressor. It draws in a larger quantity of air, which is then divided into two streams:

- Primary flow: The primary flow passes through the combustion chamber, and is therefore a hot air flow.

- Secondary flow: the secondary flow is directly ejected on either side of the engine; it’s a cold air flow that provides 80% of the thrust.

At the outlet, the cold air mixes with the warm air, resulting in cooling. Most commercial aircraft are equipped with this system, which improves thrust and reduces engine noise.

Bypass engine – Photo credit: Wikipedia

3. Ramjets

Ramjet engines are now used on fighter jets and missiles, enabling them to reach very high speeds.

- Advantages: their thrust is higher because fuel is re-injected into the combustion chamber, a process known as afterburning. What’s more, they have no moving parts and are therefore lightweight.

- Disadvantages : They require an initial speed to operate, and do not withstand extreme temperatures over time.

Superstar jet engines (like the Concorde turbojet/ramjet hybrid) reach supersonic speeds.

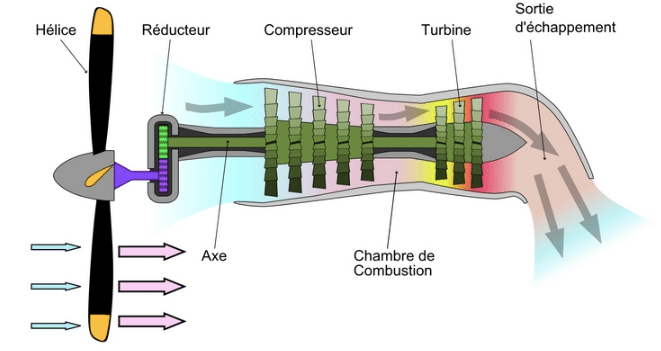

4. Turboprop engines

Turbojet engines increase thrust by ejecting as much gas as possible. This is not the case with turboprops.

They rely on the rotational power of a propeller, attached to the outside of the aircraft, to provide most of the thrust.

Turboprops offer the most economical solution for short-haul flights. They are more efficient and consume less fuel, but are limited in terms of altitude and distance.

If you’d like to find out more about the different turboprop models, visit this page.

Photo credit : Wikimedia Commons

5. Turboshaft engines (for helicopters)

Turboshaft engines were designed for helicopters. Like turbojet engines, they are equipped with a turbine.

Today’s helicopters, such as the Dauphin, feature a free turbine.

This transforms the kinetic and thermal energy of the exhaust gases into mechanical energy.

It also enables the helicopter’s blades to rotate at a different speed from that of the compressor, thus ensuring the aircraft’s stability.